Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Understanding Propane Pressure Regulator Valves: Function, Benefits, and Applications

- Pressure Regulator Valve Manufacturer

- 0-30 psi propane regulator with gauge, 1 2 propane regulator, 2 inch irrigation solenoid valve, 2 stage propane regulator vs single stage, 2-stage propane regulator for home, adjustable high pressure propane regulator, adjustable propane regulator, argon hose fitting, characteristics of pressure, gas regulator, gas used in semiconductor manufacturing, High Flow Pressure Regulators, how a solenoid valve works, industrial grade purity, low pressure regulator, low pressure regulator manufacturer, nitrogen 0-40 bar high flow pressure regulator, pressure gauge manufacturers, propane pressure regulator valves, propane pressure regulator valves factory, propane pressure regulator valves hotsale, propane pressure regulator valves manufacturer, propane pressure regulator valves supplier, propane pressure regulator valves wholesale, relief vs safety valve, safety relief valve vs pressure relief valve, solenoid valve for ammonia gas 1 inch pipe, stainless pressure regulator, water solenoid valve 24v

- No Comments

Understanding Propane Pressure Regulator Valves: Function, Benefits, and Applications

A propane pressure regulator valve is a critical component in propane systems’ safe and efficient use. It ensures propane flows at a regulated pressure, safeguarding appliances from damage while enhancing overall performance. Whether used in residential heating, cooking, or industrial applications, this valve is pivotal in maintaining the correct pressure levels for propane gas systems. This article delves into the function, advantages, and disadvantages of propane pressure regulator valves and their best uses.

What Is a Propane Pressure Regulator Valve?

A propane pressure regulator valve is a device that controls the pressure of propane gas from the tank to the appliances it powers. Propane is stored in tanks under high pressure, and the regulator valve reduces this pressure to a safe level for household or commercial appliances. This device ensures a steady flow of propane at a consistent pressure, preventing dangerous fluctuations that could cause malfunctions or even hazardous conditions.

How Does a Propane Pressure Regulator Valve Work?

The working principle behind a propane pressure regulator valve is simple but vital for the safety and efficiency of the gas system. Here’s how it works:

- High-Pressure Propane Supply:Propane is stored in liquid under high pressure in large tanks. However, this high pressure is unsuitable for direct use in most appliances.

- Pressure Regulation:The regulator valve lowers the high pressure from the propane tank to a usable level. The valve uses a spring-loaded mechanism that adjusts based on the input pressure and the desired output pressure.

- Consistent Flow:After regulating the pressure, the valve ensures a consistent gas flow to appliances, enabling them to operate safely and efficiently.

Types of Propane Pressure Regulator Valves

Propane pressure regulators come in different types to suit various applications and needs. Understanding these types helps you select the appropriate valve for your system.

Single-Stage Regulators

- Function:A single-stage propane pressure regulator reduces high tank pressure to a consistent output pressure in one step.

- Best For:Low-demand residential applications such as grilling or cooking. These regulators are commonly used when the propane tank is close to the powered appliances.

Two-Stage Regulators

- Function:A two-stage propane regulator reduces the pressure in two steps. The first stage reduces the pressure to an intermediate level, and the second stage adjusts it to the required level for appliance use.

- Best For:It is best for larger systems with varying demands or where the tank is farther from the appliances. It is ideal for homes with heating systems, multiple appliances, or remote locations.

High-Pressure Regulators

- Function:These regulators maintain high-pressure levels suitable for commercial or industrial applications.

- Best For: Large-scale operations that require more robust and high-pressure systems, such as propane-powered forklifts, outdoor heaters, and industrial ovens.

Key Features to Look for in Propane Pressure Regulators

When selecting a propane pressure regulator valve, several features must be considered to ensure the device meets your needs.

- Pressure Settings:Ensure the regulator can handle your specific application’s required input and output pressure levels.

- Durability:High-quality materials such as brass or stainless steel help prevent corrosion, ensuring a long lifespan, especially in outdoor environments.

- Safety Features:Look for regulators with built-in safety shutoff valves, which prevent gas flow in case of a leak or malfunction.

- Flow Capacity:The regulator’s flow rate must match the requirements of the appliances it serves.

Advantages of Using a Propane Pressure Regulator Valve

Using a propane pressure regulator valve offers numerous benefits, contributing to the safety and efficiency of propane-powered systems.

Enhanced Safety

- By controlling the propane pressure, the regulator ensures that gas flows safely and consistently, minimizing the risk of leaks, gas explosions, or appliance damage. It makes it an indispensable component in any propane system.

Optimized Appliance Performance

- Appliances such as stoves, heaters, and generators require optimal pressure levels. A propane pressure regulator valve ensures that these appliances receive the right amount of gas, leading to better performance, efficiency, and longer lifespan.

Prevents Overpressure Damage

- High-pressure propane can damage appliances, cause unsafe conditions, or lead to dangerous flare-ups. A regulator valve prevents overpressure by maintaining the right level, extending the life of appliances.

Energy Efficiency

- With consistent and controlled pressure, propane is used more efficiently. It reduces wastage, lowers fuel consumption, and saves costs over time.

Versatility Across Applications

- Whether for residential, commercial, or industrial use, propane pressure regulator valves come in various configurations that suit different needs. They are essential in powering everything from home cooking appliances to sizeable industrial heating systems.

Disadvantages of Propane Pressure Regulator Valves

Despite their importance, propane pressure regulator valves have drawbacks. Here are some of the limitations to consider:

Potential for Malfunctions

- Over time, wear and tear can affect the regulator valve’s performance, leading to leaks or improper pressure regulation. Regular maintenance is required to ensure safe operation.

Initial Cost

- High-quality propane regulators, especially multi-stage or high-pressure models, can be expensive upfront. However, the investment can pay off by improving the longevity and safety of propane systems.

Complexity for Some Systems

- Two-stage and high-pressure regulators can be more complex to install and require more careful consideration of the system’s needs. Incorrect installation or the use of an inappropriate regulator can lead to system inefficiencies.

Limited Adjustability

- Some regulators are designed for specific applications and may offer little flexibility in terms of pressure adjustment. It could be a limitation if your system demands more customization.

Best Uses for Propane Pressure Regulator Valves

Propane pressure regulators are essential in various fields. Here’s a breakdown of their best uses:

Residential Use

For homes, propane pressure regulators are used in:

- Gas Grills and Outdoor Cooking Equipment: Ensures a steady flame for grilling.

- Home Heating Systems:Provides regulated gas pressure to furnaces and heating units.

- Hot Water Heaters: Maintains the pressure for hot water systems.

- Backup Generators:Ensures consistent fuel pressure for propane-powered generators.

Commercial Use

In commercial settings, propane pressure regulators are used in:

- Restaurants and Foodservice:Regulate the propane used for cooking appliances like stoves and ovens.

- Industrial Heating:This keeps large-scale propane heaters operating at optimal pressure.

- Forklifts and Other Equipment:Many warehouses and factories use propane-powered machinery, which relies on pressure regulators for safe operation.

Industrial Applications

Propane pressure regulators are critical for industrial uses such as:

- Manufacturing Plants:Regulators ensure consistent fuel pressure for large industrial ovens, furnaces, and kilns.

- Agricultural Operations:Propane is often used on large farms to power irrigation pumps, heat greenhouses, and power machinery.

- Outdoor Heating Systems:Portable heaters in outdoor workspaces, events, or construction sites rely on propane pressure regulators to maintain safe and efficient operations.

Maintenance and Care of Propane Pressure Regulators

Proper maintenance is necessary to ensure the safe and efficient functioning of your propane pressure regulator valve. Here are a few tips:

- Inspect Regularly: Periodically check the regulator for signs of wear, corrosion, or leakage. Replace worn parts as needed.

- Clean the Regulator: Dust, dirt, and debris can affect the regulator’s performance. Clean the valve and surrounding components regularly.

- Check for Leaks:Use a soapy water solution for leaks around the regulator. Bubbles indicate a leak that needs immediate attention.

- Replace if Necessary:If the regulator is not functioning correctly or shows signs of failure, replace it promptly to avoid dangerous situations.

Conclusion

A propane pressure regulator valve is an indispensable part of any propane system, providing safety, efficiency, and performance. It ensures propane flows at a regulated pressure, preventing damage to appliances and ensuring optimal operation. While the advantages far outweigh the disadvantages, it is essential to maintain these valves properly to ensure long-term functionality. You can make the most out of your propane-powered appliances and systems by understanding how they work, their uses, and how to care for them. Whether for residential, commercial, or industrial use, propane pressure regulator valves ensure safe and reliable operations.

For more about understanding propane pressure regulator valves: function, benefits, and applications, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Tags

Recommended Products

-

Stainless Steel Ultra High Purity Mini Butt Weld Mini Tee Reducer MTRW Series Fittings

-

Stainless Steel Low Pressure Seal Pneumatic Diaphragm Control Valve For For HP & UHP Gases

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process

-

764L Stainless Steel Union Tee High Purity Fitting Union Tee Reducing Tubing Connection

-

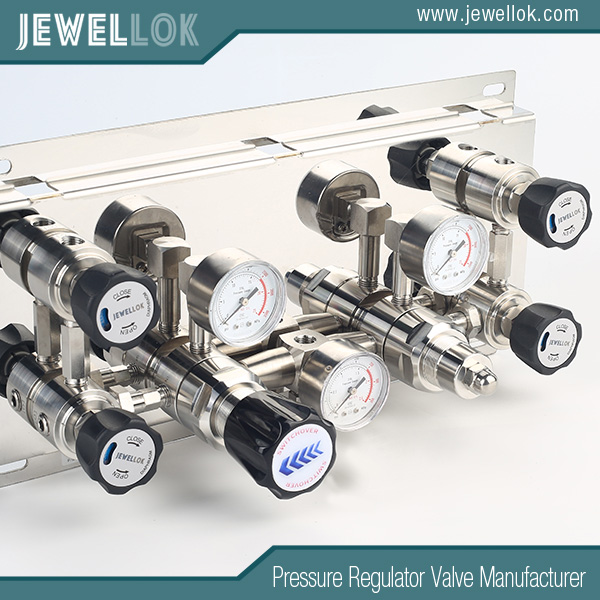

High Purity High Flow Pressure Control Regulators & Valves Gas Stick Assemblies JSR-2TG Series

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series

-

765LR Reducing Tee | Stainless Steel 316 High Purity Butt Weld Fittings Metal Face Seal For Welding Pipe Fitting Reducing Tee

-

768L Stainless Steel Male Tube Butt Weld Connector | Clean Weld Fittings And Ultra-High Purity Fittings