Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Understanding Pneumatic Actuated Ball Valves: Function, Applications, And Benefits

- Pressure Regulator Valve Manufacturer

- Ball Valve with Pneumatic Actuator, China Pneumatic Actuator Ball Valve Manufacturers, pneumatic actuated ball valve, pneumatic actuated ball valve 3d model, pneumatic actuated ball valve india, pneumatic actuated ball valve manufacturer in china, pneumatic actuated ball valve manufacturers, pneumatic actuated ball valve symbol, pneumatic actuator ball valve manufacturers, pneumatic actuator ball valve working principle, Pneumatic ball valve manufacturer

- No Comments

Understanding Pneumatic Actuated Ball Valves: Function, Applications, And Benefits

Pneumatic actuated ball valves are critical in various industries, offering flexibility and precision in controlling fluid and gas flow. These valves utilize pneumatic (air-driven) actuators to open, close, or modulate the flow of materials through pipelines or systems. Integrating pneumatic technology with ball valves has made them a go-to choice for processes requiring reliable, high-performance flow control. This article explores the design, operation, benefits, and various applications of pneumatic actuated ball valves, shedding light on why they are favored in industries ranging from oil and gas to manufacturing.

What is a Pneumatic Actuated Ball Valve?

Overview of Ball Valves

- Ball valves are a type of quarter-turn valve with a spherical ball that controls the flow of liquids or gases. The ball has a hole in the middle, and when it is rotated, the hole either aligns with the pipeline to allow flow or moves out of alignment to block it. Ball valves are known for their durability, reliability, and simplicity in operation.

Pneumatic Actuators

- An actuator is a device used to control the movement of a valve. Pneumatic actuators use compressed air to produce mechanical motion, typically linear or rotary. When the actuator receives air pressure, it moves a piston or diaphragm, which drives the valve into the desired position.

How Pneumatic Actuated Ball Valves Work

The operation of a pneumatic actuated ball valve can be broken down into a few key steps:

- Signal Initiation: The actuator receives a signal, typically compressed air, that activates the mechanism.

- Movement of the Actuator: The pneumatic actuator moves a piston or diaphragm, which rotates the ball valve.

- Valve Position: The ball valve either opens, closes, or modulates the flow based on the actuator’s position.

- Flow Control: The fluid or gas flow is allowed, blocked, or regulated according to the system’s needs.

Key Features of Pneumatic Actuated Ball Valves

- Quick Response Time: Pneumatic actuators allow for rapid valve opening or closing, which is ideal for systems that need to respond quickly to changing conditions.

- Remote Operation: Pneumatic actuators can be controlled remotely, allowing operators to maintain flow without being on-site.

- Durability: Pneumatic actuators, combined with the robust nature of ball valves, create a system that can withstand harsh environments and frequent use.

- Precision: Pneumatic actuators provide accurate and consistent control over flow rates.

Benefits of Pneumatic Actuated Ball Valves

Pneumatic actuated ball valves offer numerous advantages, making them an ideal solution for many industrial applications. Below are some of the key benefits:

Efficiency and Speed

- Rapid Operation: Pneumatic actuated ball valves operate quickly, offering nearly instantaneous changes in flow control. This makes them suitable for systems requiring fast action, such as chemical processing or power plants.

- Energy Efficiency: Pneumatic actuators are relatively simple and inexpensive to operate. They require only compressed air, often readily available in industrial settings.

Reliability

- Durability: These valves are designed to withstand extreme conditions, including high pressure and temperature variations. The robust nature of ball valves ensures long service life, reducing the need for frequent maintenance or replacement.

- Minimal Wear and Tear: Due to their design, pneumatic actuated ball valves experience minimal wear during operation, contributing to their reliability and extended lifespan.

Cost-Effectiveness

- Lower Maintenance Costs: Pneumatic actuated ball valves require less maintenance than electric or hydraulic actuators, resulting in lower ongoing operational costs.

- Affordable Components: Pneumatic systems, particularly in large-scale industries, can be less expensive to install and operate than alternatives such as electric actuators.

Safety Features

- Fail-Safe Operation: Pneumatic actuated ball valves often come with fail-safe mechanisms, ensuring the valve either closes or opens automatically if there is a loss of air supply or system pressure. This enhances the safety of the entire system.

- Built-in Pressure Relief: Many models come equipped with a built-in pressure relief feature to prevent damage to the valve or system in case of sudden pressure changes.

- Versatility and Customization

- Wide Range of Applications: These valves can control both gases and liquids, making them suitable for a variety of industries, such as pharmaceuticals, oil and gas, food and beverage, and water treatment.

- Adjustable Stroke Lengths: Pneumatic actuators can be customized to achieve specific stroke lengths for precise flow control, adding versatility to the application.

Applications of Pneumatic Actuated Ball Valves

Pneumatic actuated ball valves are used across many industries. Below are some critical applications:

Oil and Gas Industry

- Flow Control: In the oil and gas sector, pneumatic actuated ball valves control oil flow, natural gas, and associated liquids.

- Safety Shutoff: They provide crucial shutoff capability during emergencies, preventing the accidental release of hazardous materials.

Chemical and Petrochemical Processing

- Corrosive Fluid Handling: Ball valves with pneumatic actuators are ideal for handling corrosive or hazardous chemicals, thanks to their ability to stop or regulate flow quickly.

- Precise Control: They offer precise regulation of fluid flow, which is essential for chemical reactions requiring accurate dosing or mixing of ingredients.

Water Treatment and Distribution

- Flow Regulation: Pneumatic actuated ball valves are commonly used in water treatment plants to regulate flow through various filtration and purification stages.

- Pressure Control: They help manage pressure levels in distribution systems, ensuring stable consumer flow.

Power Generation

- Steam Control: In power plants, these valves help control the flow of steam and water, ensuring optimal performance of turbines and boilers.

- Quick Shut Off: Pneumatic actuated ball valves provide fast and reliable shutoff capabilities in power generation facilities, minimizing downtime and maximizing efficiency.

Pharmaceuticals

- Accurate Dosing: In the pharmaceutical industry, pneumatic actuated ball valves are used to precisely control the flow of liquids and gases in the manufacturing of medicines, vaccines, and other healthcare products.

- Sterility: Given the need for sterile conditions, these valves are often made of materials resistant to corrosion and bacteria, ensuring a clean flow path.

Types of Pneumatic Actuators

There are two primary types of pneumatic actuators used in ball valves:

1. Double-Acting Pneumatic Actuators

- Description: Double-acting actuators use air pressure to move the valve in both directions either to open or close. They typically require air to both open and close the valve.

- Application: These actuators are ideal in applications where the valve needs to operate in both directions without relying on spring tension for one direction.

2. Spring-Return Pneumatic Actuators

- Description: Spring-return actuators use air pressure to open the valve, while a spring mechanism automatically closes it when the air pressure is released.

- Application: Spring-return actuators are used in applications that require a fail-safe mechanism. They ensure that the valve closes automatically in the event of an air supply failure.

Conclusion

Pneumatic actuated ball valves are essential in modern industrial processes, providing efficient, reliable, and precise control over fluid and gas flow. Their versatility, speed, and ability to operate remotely make them an ideal solution for various applications, from the oil and gas industry to water treatment, pharmaceuticals, and food processing. Integrating pneumatic actuators with ball valve technology results in cost-effective and robust systems with minimal maintenance needs and long service life. With their combination of performance and reliability, pneumatic actuated ball valves

For more about understanding pneumatic actuated ball valves: function, applications, and benefits, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Tags

Recommended Products

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases

-

High Purity Stainless Steel Mini Tube Butt Weld Fittings For Semiconductor

-

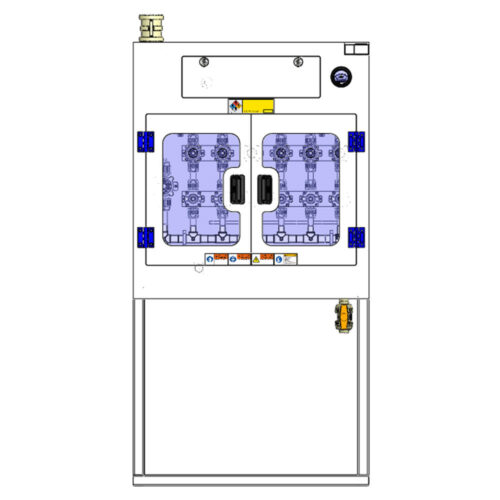

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

Manual Gas Rack High Purity Gas Delivery Systems JW-100-GR

-

772L Male Branch Tee | Stainless Steel High-Purity Tube Fitting Male Branch Tee

-

7108L Cylinder Cap Connectors For Ultra High Purity Gases

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control

-

767LT Reducer Pressure Reducing Valve Adjustment High purity Pressure Reducing Union Fittings And Tubing