Pressure Regulator & Valves Technology

A pressure regulator is a valve that controls the pressure of a fluid to a desired value, using negative feedback from the controlled pressure. Regulators are used for gases and liquids, and can be an integral device with a pressure setting, a restrictor and a sensor all in the one body, or consist of a separate pressure sensor, controller and flow valve.

Regulators, Valves and Systems deliver a wide range of standard and custom engineered precision pressure control solutions for a diverse world market.

Valve Body Material Compatibility

There are several factors to consider when choosing material for your valves. First, you need to consider what media they will handle. The material must be able to withstand the media normally present in the line as well as media that may enter the line or the external environment around the valve.

Valve Heat And Surface Treatments

When it comes to selecting light alloys, most engineers do not venture far from Al, Mg and Ti alloys. However, this article explores the uses and benefits of some of those lesser used light alloys, such as Zirconium, Tantalum and Hafnium.

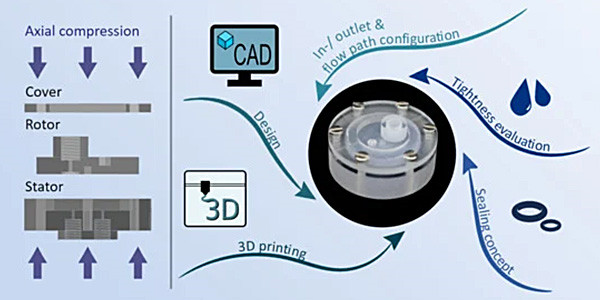

CAD & 3D Prototyping For Pressure Regulator & Valve

Prototyping is an extremely important step in product development. Prototyping custom manufactured parts, in particular, provides the opportunity to evaluate your design, demonstrate its concept, inspect it for flaws, correct any issues, and improve overall design. However, traditional prototyping can be a very time-consuming and expensive process.

Valves Cleaning

Other media that require this level of cleanliness include numerous other pure gases, chlorine, paints and some chemicals. What all this means is that a standard, off-the-shelf valve cannot be used in these media unless it has been properly processed before installation. Decades ago, achieving this degree of cleanliness required the use of vapor degreasing machinery filled with a chlorinated solvent such as trichloroethane.

Pressure And Leak Testing

Leak testing is a procedure that inspectors use to determine whether an object or system is functioning within a specific leak limit. Leaks occur when there is a defect—a hole, crack, or some other kind of flaw—in an object, allowing whatever the liquid or gas it is holding to flow out. Leak testing uses pressure to find these defects so that they can be addressed as part of regular maintenance procedures.

Pressure Regulator

A pressure regulator is a valve that controls the pressure of a fluid to a desired value, using negative feedback from the controlled pressure. Regulators are used for gases and liquids, and can be an integral device with a pressure setting, a restrictor and a sensor all in the one body, or consist of a separate pressure sensor, controller and flow valve.

Basics of Pressure Regulator

Pressure Regulators are found in many common home and industrial applications. For example, pressure regulators are used in gas grills to regulate propane, in home heating furnaces to regulate natural gases, in medical and dental equipment to regulate oxygen and anesthesia gases, in pneumatic automation systems to regulate compressed air, in engines to regulate fuel and in fuel cells to regulate hydrogen.

Choosing the Right Types of Pressure Regulators for Your Application

If you manage an industrial fluid system, you know that maintaining precise process conditions is often an operational imperative. Pressure represents one of your most important conditions, and maintaining desired pressure levels requires the right type of industrial pressure regulator in your system.

Welding Pressure Regulator

A welding regulator regulates high-pressure gas from a cylinder to ensure the gas is at the optimal delivery pressure required for a welding application. Without a regulator, inconsistent, excessively high, or low pressure can be dangerous and negatively impact the quality of the weld, resulting in porosity, fissures, or cracks.