Blog

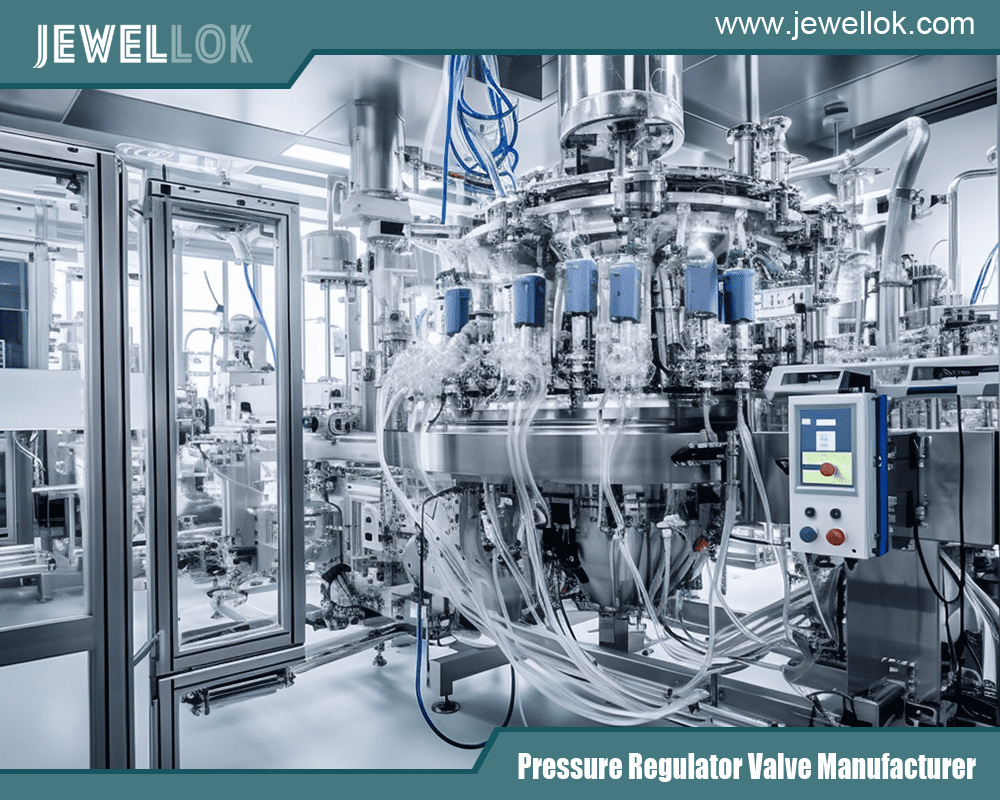

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Pressure Safety Valve vs Relief Valve: Understanding the Key Differences and Applications

- Pressure Regulator Valve Manufacturer

- adjustable propane regulator, adjusting propane regulator, argon hose fitting, bcf connector, characteristics of pressure, chinese propane gas cylinder, diaphragm suppliers, double block and bleed valve, double block and bleed valve diagram, excess flow valve, fusible plug, gas filter, gas regulator, gas used in semiconductor manufacturing, high pressure flexible hose, how a solenoid valve works, hydraulic regulator, industrial grade purity, low pressure regulator, pressure gauge manufacturers, pressure relief valve vs safety relief valve, pressure safety valve vs relief valve, quick connect valve, relief vs safety valve, safety relief valve vs pressure relief valve, solenoid valve for ammonia gas 1 inch pipe, solenoid water valve, stainless pressure regulator, ultra high purity, water solenoid valve 24v, what is a gas pressure regulator

- No Comments

Pressure Safety Valve vs Relief Valve: Understanding the Key Differences and Applications

Pressure management is critical to maintaining the safety and functionality of many industrial systems. Two essential components that play a vital role are pressure safety valves (PSVs) and pressure relief valves (PRVs). While both devices are designed to protect systems from excessive pressure, they operate differently and are suited to distinct applications. Understanding the differences between pressure safety and relief valves is vital for engineers and technicians designing, maintaining, or operating pressure systems. This article explores the differences, functionalities, applications, and critical considerations for using PSVs and PRVs to ensure optimal system performance and safety.

Understanding Pressure Safety Valves (PSVs)

Definition and Function

A pressure safety valve (PSV) is a specialized device to protect a system from pressure exceeding safe operational limits. PSVs are typically used in systems where rapid and drastic pressure changes could lead to damage, catastrophic failure, or unsafe conditions. When the system pressure exceeds the set limit, the PSV opens to release excess pressure and prevent the pressure from rising further.

Working Principle of PSVs

The working principle of a PSV revolves around the spring-loaded mechanism, which holds a valve in a closed position until the system pressure exceeds the preset limit. Once the pressure reaches a critical point, the spring compresses, and the valve opens, allowing the excess pressure to be vented. The spring closes the valve when the pressure drops back to a safe level.

Understanding Pressure Relief Valves (PRVs)

Definition and Function

A pressure relief valve (PRV) is designed to protect pressure systems by releasing pressure exceeding the set limit. While they may look similar to PSVs, PRVs are typically used in liquid systems where pressure surges or overpressures could damage the equipment or pipes. PRVs are essential for maintaining the system’s stability, especially in applications that involve pumping liquids or gases under high pressure.

Working Principle of PRVs

The principle behind the operation of a pressure relief valve is similar to that of a PSV. The PRV is set to open when the pressure inside the system exceeds the predetermined threshold. The valve opens, and the pressurized fluid is released to maintain safety. The valve closes after the pressure returns to normal, maintaining the system’s integrity.

Pressure Safety Valve vs Relief Valve: Key Differences

Although both PSVs and PRVs are used to control excessive pressure, their design and applications differ in some essential aspects. Let’s explore the main differences between pressure safety valves and relief valves:

Design and Construction

- PSVs:PSVs are primarily spring-loaded valves designed for gas or vapor systems. They are built to handle rapid, significant pressure changes and often feature a quick-release mechanism to control the system’s pressure instantly.

- PRVs:PRVs are usually employed in liquid systems with a more gradual pressure-release mechanism. They are often equipped with a diaphragm or piston system, rather than a spring, for smoother operation under varying pressure conditions.

Set Pressure Range

- PSVs:The set pressure of a PSV is typically higher, as they are designed for systems where high-pressure surges are expected. These valves are designed to open and close quickly to mitigate pressure spikes.

- PRVs:The pressure set by a PRV is generally lower than that of a PSV. PRVs are intended to maintain more consistent pressure in liquid systems, gradually releasing pressure and providing continuous control over pressure levels.

Application Areas

- PSVs:PSVs are commonly found in industries involving steam, gas, and other vapor systems where rapid pressure fluctuations could occur. They are ideal for boilers, pressure vessels, and pipeline systems.

- PRVs:PRVs are typically used in liquid-based systems, such as water, hydraulic, and oil systems, where pressure fluctuations are more gradual. They are frequently used in plumbing, heating systems, and chemical processing plants.

Why Choose One Over the Other?

Factors to Consider

The decision between a PSV and a PRV largely depends on the specific application, pressure conditions, and the type of fluid involved. Here are some factors to consider when choosing the appropriate valve:

- Nature of Fluid:Gas and vapor systems are better suited for PSVs because they handle rapid pressure surges. Liquids, on the other hand, are more commonly controlled by PRVs.

- System Design:The complexity of the system and the type of equipment involved may dictate the choice between the two valves.

- Pressure Variability:PRVs may be more suitable for systems with consistent or lower pressure fluctuations, while PSVs are better for systems with large pressure fluctuations.

Choosing Between a PSV and PRV

- Use PSVs:In applications operating under high-pressure conditions or with gases and vapors, such as steam boilers, compressed air systems, and specific chemical processes.

- Use PRVs: Use PRVs for systems involving liquids or more gradual pressure changes, such as water treatment facilities, oil pipelines, and hydraulic systems.

Applications of Pressure Safety and Relief Valves

Both pressure safety and relief valves are essential in various industries. Below are the common sectors where these valves are used:

- Oil and Gas Industry:PSVs are often used to protect pipelines, pressure vessels, and equipment from overpressure, which can be dangerous when transporting gases and vapors.

- Chemical Processing:PSVs and PRVs manage the pressure of chemical systems, with PSVs typically used in vapor-rich environments and PRVs employed for liquids and slurries.

- Power Generation:PSVs are crucial in power plants, especially in steam and gas turbine systems where maintaining pressure is vital for operational safety.

- Manufacturing:In various manufacturing processes, pressure relief valves help regulate the flow of fluids, ensuring the safe operation of equipment like pumps and compressors.

- Plumbing and HVAC Systems:PRVs are commonly used in water and HVAC systems to maintain stable pressure levels, prevent pipe damage, and avoid system failures.

Benefits of Using Pressure Safety Valves

Pressure safety valves offer several advantages:

- Rapid Response:PSVs react quickly to sudden pressure surges, minimizing the risk of system damage.

- Enhanced Safety:By quickly relieving excess pressure, PSVs prevent catastrophic failures in systems such as boilers and pressure vessels.

- Regulatory Compliance:In many industries, the installation of PSVs is a legal requirement to meet safety standards.

Benefits of Using Pressure Relief Valves

Pressure relief valves also offer unique benefits, including:

- Smooth Pressure Control:PRVs provide continuous control, helping systems maintain a consistent pressure level, which is crucial in liquid-based systems.

- Cost-Effective Maintenance:With regular maintenance, PRVs can ensure long-term reliability, offering an economical solution to pressure management.

- Preventing Overpressure Damage:PRVs help prevent leaks, pipe bursts, and other issues associated with excessive pressure in liquid systems.

Maintenance Considerations for PSVs and PRVs

Proper maintenance ensures that both PSVs and PRVs function effectively over time. Here are some essential maintenance considerations:

- Inspection:Regular inspection of valve components (such as seals and springs) is crucial to prevent failure.

- Cleaning:The valves must be cleaned periodically to ensure they are free of debris that may prevent them from functioning correctly.

- Testing:Regular testing to verify that the valves open and close at the correct pressures is necessary to maintain system safety.

- Replacement of Parts:Over time, parts such as springs, diaphragms, and seals may wear out and need replacing to maintain valve effectiveness.

Conclusion

In summary, understanding the differences between pressure safety valves and pressure relief valves is essential for ensuring the safety and efficiency of industrial systems. While both devices perform the critical task of managing excessive pressure, their design, functionality, and applications are distinct. PSVs are typically used in gas and vapor systems, providing rapid pressure relief to prevent catastrophic damage. At the same time, PRVs are designed for liquid systems, offering a gradual and continuous pressure release to ensure system stability.

For more about pressure safety valve vs relief valve: understanding the key differences and applications, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Tags

Recommended Products

-

High Pressure High Temperature Pneumatic Ultrahigh Purity Stainless Steel Diaphragm Valves

-

High Purity Stainless Steel Mini Tube Butt Weld Fittings For Semiconductor

-

7121L Plug High Purity Plug Fitting And Blanking Plug

-

Stainless Steel Single Stage Semiconductor Grade Pressure Control Module Pressure Control Panels JSP-6A Series

-

DPR1 Ultra High Purity Two Stage Dual Stage Pressure Reducing Regulator Semiconductor Grade Regulators

-

765LR Reducing Tee | Stainless Steel 316 High Purity Butt Weld Fittings Metal Face Seal For Welding Pipe Fitting Reducing Tee

-

Pressure Control Panels For High Purity Gas Control System JSP-3AE Series From Pressure Control Panels Suppliers And Manufacturer

-

767LP Port Connector Ultra High Purity VCR Metal Gasket Face Seal Tube Fittings