Blog

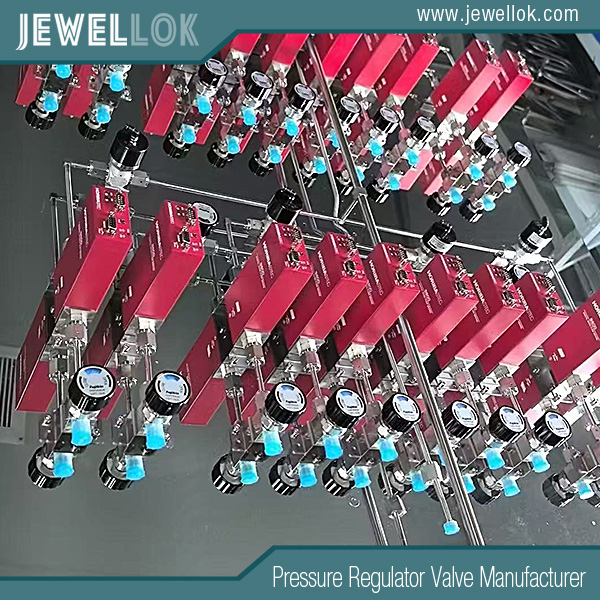

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

High Pressure Nitrogen Gas Regulator: An Essential Tool for Industrial Applications

- Pressure Regulator Valve Manufacturer

- adjustable low pressure propane regulator, adjusting propane regulator, argon hose fitting, bcf connector, block & bleed valve, characteristics of pressure, chinese propane gas cylinder, double block and bleed valve, excess flow valve, fusible plug, gas filter, gas regulator, high pressure flexible hose, high pressure nitrogen gas regulator, high pressure nitrogen gas regulator factory, high pressure nitrogen gas regulator hotsale, high pressure nitrogen gas regulator manufacturer, high pressure nitrogen gas regulator OEM, high pressure nitrogen gas regulator supplier, high pressure nitrogen gas regulator wholesale, how a solenoid valve works, how solenoid works, hydraulic regulator, industrial grade purity, low pressure regulator, o ring face seal fittings, pressure gauge fitting - 3/8 qc, pressure gauge manufacturers, pressure relief valve vs safety relief valve, quick connect valve, safety relief valve vs pressure relief valve, solenoid valve for ammonia gas 1 inch pipe, solenoid valve for ammonia gas 2 inch pipe, solenoid water valve, water solenoid valve 24v

- No Comments

High Pressure Nitrogen Gas Regulator: An Essential Tool for Industrial Applications

In various industries, from manufacturing to research and medical fields, high-pressure nitrogen gas regulators are vital tools that ensure controlled and precise management of nitrogen gas flow. Nitrogen, an inert gas commonly used in applications such as welding, electronics manufacturing, and chemical processes, needs to be carefully regulated to avoid accidents and ensure optimal operation. A high-pressure nitrogen gas regulator plays a crucial role in reducing the pressure of nitrogen gas from a cylinder or tank, making it safe and suitable for use in different systems.

What is a High Pressure Nitrogen Gas Regulator?

A high-pressure nitrogen gas regulator is a device designed to control the pressure of nitrogen gas coming from high-pressure cylinders or tanks. It reduces the gas pressure from the cylinder’s high pressure to a lower, more manageable pressure suited for industrial applications. Nitrogen gas regulators are equipped with mechanisms to adjust the flow rate, ensuring a steady and controlled supply of nitrogen for processes that require specific gas pressure levels.

Critical Functions of a High Pressure Nitrogen Gas Regulator

Pressure Reduction: The primary function of a nitrogen gas regulator is to reduce the high pressure from nitrogen cylinders to a more manageable and safer pressure for use in equipment or applications.

- Flow Control:A regulator ensures that nitrogen flows at a constant rate, essential for maintaining optimal operating conditions in various industrial systems.

- Safety Assurance:By maintaining a consistent pressure and flow rate, nitrogen gas regulators help prevent system overpressure, which could lead to hazardous situations like leaks or equipment failure.

Types of High Pressure Nitrogen Gas Regulators

High-pressure nitrogen gas regulators come in different designs, each suited for specific applications and requirements. Understanding these types will help you select the appropriate one for your needs.

Single-Stage Regulators

Single-stage regulators are ideal for applications where the nitrogen gas pressure needs to be reduced in one step. These regulators directly reduce the pressure from the cylinder to the desired output pressure.

Advantages:

- Simple in design and easy to operate.

- Cost-effective for low-to-medium pressure applications.

Disadvantages:

- Less precise in maintaining output pressure if the supply pressure fluctuates.

Two-Stage Regulators

Two-stage regulators incorporate two stages of pressure reduction to provide a more refined pressure reduction process. This design ensures a more stable output pressure even if the input pressure fluctuates.

Advantages:

- More consistent and stable output pressure.

- It is better for applications requiring precise pressure control.

Disadvantages:

- More expensive than single-stage regulators.

- It’s a slightly more complex design.

Multi-Stage Regulators

Multi-stage regulators offer the highest level of precision by using several stages to reduce pressure in a more controlled manner. These regulators are typically used in high-demand industries such as laboratories, pharmaceuticals, and research centers.

Advantages:

- Extremely stable and accurate pressure control.

- Suitable for applications that require constant pressure despite fluctuations in supply.

Disadvantages:

- More expensive.

- More significant and bulkier in design.

High-Flow Regulators

High-flow nitrogen gas regulators are designed to handle large volumes of nitrogen gas at high pressures. They are commonly used in welding, cutting, and large-scale manufacturing industries.

Advantages:

- Can handle large amounts of gas efficiently.

- Suitable for high-demand industrial processes.

Disadvantages:

- Larger and more expensive than standard regulators.

Applications of High Pressure Nitrogen Gas Regulators

High-pressure nitrogen gas regulators are used in a wide range of industries where the need for nitrogen gas is prevalent. Below are some of the critical applications:

Welding and Metal Fabrication

- Nitrogen gas shields the welding area from atmospheric gasses that could interfere with the process. A high-pressure nitrogen gas regulator is crucial for controlling the nitrogen flow to the welding torch, ensuring a steady gas supply for effective shielding.

Benefits:

- Ensures clean welds by preventing oxidation.

- Provides stable shielding gas pressure during welding.

Chemical and Pharmaceutical Manufacturing

- Nitrogen is widely used in chemical and pharmaceutical manufacturing to prevent oxidation and other reactions that could alter the product quality. High-pressure nitrogen gas regulators help control the nitrogen atmosphere in reactors and storage vessels.

Benefits:

- Provides an inert atmosphere for reactions.

- Prevents contamination and degradation of sensitive materials.

Food Packaging and Preservation

- Nitrogen gas is used in the food industry as a packaging material. By replacing oxygen in the packaging environment, nitrogen extends the shelf life of food products. A high-pressure nitrogen gas regulator ensures a constant nitrogen flow into packaging machines.

Benefits:

- Maintains product freshness.

- Increases shelf life by reducing oxygen levels.

Electronics Manufacturing

- In the electronics industry, nitrogen creates a controlled environment for producing components like semiconductors and circuit boards. High-pressure nitrogen gas regulators are essential for managing the nitrogen pressure used in these sensitive manufacturing processes.

Benefits:

- Prevents oxidation and contamination during production.

- Provides a stable environment for sensitive electronics.

Medical Applications

- In the medical field, nitrogen gas is used in cryogenics and to preserve biological samples. High-pressure nitrogen gas regulators control the nitrogen supply, ensuring cryogenic storage units’ safe and efficient operation.

Benefits:

- Ensures precise nitrogen flow for medical and research purposes.

- Vital for maintaining the integrity of stored biological samples.

Key Features to Look for in a High Pressure Nitrogen Gas Regulator

Several factors must be considered when selecting a high-pressure nitrogen gas regulator to ensure it meets the specific application’s requirements. Below are the essential features to look for:

- Pressure Range:Ensure the regulator is designed for the specific pressure range required for your application.

- Flow Rate Capacity:Different applications require varying flow rates, so choosing a regulator to handle the necessary gas flow is essential.

- Material Construction:Look for regulators made from corrosion-resistant materials like stainless steel, especially if the gas will come into contact with moisture or other chemicals.

- Accuracy:A regulator with high accuracy will provide consistent and stable pressure, which is essential for precision applications.

- Safety Features:Look for regulators with built-in safety mechanisms such as pressure relief valves to prevent over-pressurization.

Key Considerations

- Compatibility:Ensure the regulator is compatible with the type of nitrogen cylinder or tank used.

- Ease of Use:Choose a regulator that is easy to operate, adjust, and maintain.

- Durability:Consider the durability of the regulator, especially if it will be exposed to harsh industrial environments.

Maintenance and Care of High Pressure Nitrogen Gas Regulators

Maintaining your high-pressure nitrogen gas regulator is crucial to ensure its long-term functionality and safety. Regular inspection and maintenance can help detect and prevent potential issues before they affect the operation.

Regular Inspection

- Inspect for leaks regularly by using a soap solution to detect escaping gas.

- Check for corrosion or signs of wear, especially on the regulator’s components.

- Ensure the pressure gauge is functioning correctly and providing accurate readings.

Cleaning and Replacing Parts

- Clean the regulator’s filter and valve periodically to ensure optimal performance.

- Replace worn-out or damaged seals to prevent leaks.

- Ensure the regulator’s components are correctly lubricated where necessary.

Calibration

- Calibrate the regulator to ensure it maintains the correct pressure over time.

- A qualified technician should do it to ensure accuracy.

Conclusion

A high-pressure nitrogen gas regulator is an essential component in various industries. It ensures that nitrogen gas is safely and efficiently supplied at the appropriate pressure for different applications. The proper regulator ensures safety, precision, and optimal performance for welding, food preservation, chemical processes, or medical uses.

For more about high pressure nitrogen gas regulator: an essential tool for industrial applications, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Tags

Recommended Products

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases

-

Stainless Steel Ultra High Purity (UHP) High Pressure Manual Diaphragm Valve

-

762L Stainless Steel High Purity Union High-Purity Gas System Fittings

-

VMB Valve Manifold Panels And Boxes High Purity Configurable Systems JW-200-VMB & JW-100-VMB

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing

-

High Purity High Pressure 316 Stainless Steel Ball Valves JBV1 Series From High Pressure Ball Valve Manufacturer And Supplier In China

-

7108L Cylinder Cap Connectors For Ultra High Purity Gases