Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Gas Chromatography Valves for the Semiconductor Industry: Ensuring Precision and Efficiency in Analytical Processes

- Pressure Regulator Valve Manufacturer

- 2 inch irrigation solenoid valve, 300 size cylinder, 6mm equivalent, adjustable propane regulator with gauge, adjusting propane regulator, argon hose fitting, argon suppliers, characteristics of pressure, chinese propane gas cylinder, diaphragm suppliers, gas used in semiconductor manufacturing, high pressure flexible hose, how a solenoid valve works, how does pressure regulator work, how solenoid valves work, hydrogen gas regulator, industrial grade nitrogen purity, kwe css, low pressure nitrogen regulator, nitrogen gas filter, nitrogen high pressure regulator, pressure gauge manufacturers, pressure relief valve vs safety relief valve, relief vs safety valve, safety relief valve vs pressure relief valve, solenoid valve for ammonia gas 1 inch pipe, solenoid water valve, stainless pressure regulator, stainless steel 1/4 in. pressure gauge fitting - 3/8 qc, water solenoid valve 24v, what is a gas pressure regulator

- No Comments

Gas Chromatography Valves for the Semiconductor Industry: Ensuring Precision and Efficiency in Analytical Processes

In the modern semiconductor industry, the need for precision and accuracy in analysis and testing has never been more critical. Gas chromatography (GC) has long been a vital analytical technique for separating and analyzing compounds in gas and liquid samples, providing valuable insights into the chemical composition of materials. Within the semiconductor industry, gas chromatography plays a crucial role in the testing and quality control of materials, ensuring that components meet the rigorous standards required for manufacturing advanced electronic devices. An integral part of the GC system is the valves, which control the flow of gases and samples, ensuring that measurements are reliable and reproducible.

This article explores the importance of gas chromatography valves in the semiconductor industry, delving into their functions, types, and benefits. By understanding how these components contribute to the overall performance of GC systems, semiconductor manufacturers can improve testing protocols, streamline production, and enhance product quality.

The Role of Gas Chromatography in the Semiconductor Industry

Gas chromatography (GC) is a widely used technique in the semiconductor industry for analyzing volatile compounds, including solvents, residual chemicals, and gases, that can influence the manufacturing process of semiconductor materials. Given the sensitivity of semiconductor devices to contamination, it is vital to monitor trace elements in raw materials and end products to maintain production integrity.

The primary application of gas chromatography in the semiconductor sector includes:

- Detection of Impurities:Semiconductor materials must meet high purity standards, and even trace impurities can significantly affect the performance of semiconductor devices. GC helps detect and quantify these contaminants.

- Quality Control:Ensuring the quality of materials used in semiconductor manufacturing involves rigorous testing of gases, chemicals, and solvents. GC provides accurate data on chemical composition and purity.

- Environmental Monitoring:Gas chromatography also monitors environmental emissions from semiconductor manufacturing processes, which may include volatile organic compounds (VOCs) or other hazardous gases.

In these applications, the precision of the GC system is critical, and gas chromatography valves play a crucial role in this regard.

Understanding Gas Chromatography Valves

In a typical gas chromatography setup, the sample is injected into a carrier gas stream, and the components of the sample are separated as they pass through a column. The valves control the flow of gases and samples through the GC system, facilitating the efficient injection, separation, and detection of compounds. These valves provide precise and repeatable control over the system’s fluid and gas paths.

Gas chromatography valves can be found in various parts of the GC system, including:

- Sample Injection Valve: Regulates the introduction of the sample into the column.

- Column Switching Valve: Used in methods that require changing the flow path, such as multi-dimensional GC setups.

- Gas Switching Valves: These valves direct the flow of carrier or other gases used in the system to ensure consistent analysis.

Key Features of Gas Chromatography Valves for Semiconductor Applications

Gas chromatography valves in the semiconductor industry must meet specific requirements to ensure the highest performance, durability, and precision. These valves must be capable of handling high-purity gases, maintaining tight seals, and withstanding the operational demands of an analytical laboratory. Some of the critical features of GC valves include:

- Leak-tight Construction: Given the sensitivity of semiconductor analysis, valves must prevent any leakage of gases or contaminants that could compromise test results.

- Corrosion Resistance: Semiconductor applications often involve aggressive chemicals or gases, so valves must be made from materials that resist corrosion and degradation over time.

- Minimal Dead Volume: Dead volume refers to the areas within the valve where gases or samples may accumulate. Minimizing dead volume ensures that samples are transferred efficiently and without contamination.

- High Pressure and Temperature Tolerance:Many GC systems operate at high pressures and temperatures, and valves must be able to withstand these conditions without failing.

- Precision Control: Accurate flow control is critical in GC analysis, and the valves must provide smooth, reproducible adjustments to ensure consistent results.

Types of Gas Chromatography Valves Used in Semiconductor Testing

There are several types of gas chromatography valves, each suited for different applications within the semiconductor industry. These valves vary in complexity, materials, and functionality, depending on the specific needs of the analysis.

- Rotary Valves: Rotary Valves are commonly used for sample injection and switching gas lines. They provide a reliable means of controlling flow and can be adjusted precisely.

- Solenoid Valves: These electrically controlled valves use solenoids to open and close the valve. They are often used in automated GC systems requiring precise timing and remote operation.

- Pneumatic Valves: Controlled by compressed air or gas, pneumatic valves are often used where quick, precise valve switching is needed.

- Manual Valves:Although manual valves are less common in automated systems, they are still used in some setups for their simplicity and reliability, especially in research laboratories.

- Multiple-port Valves: These valves have multiple channels and are used in systems that require the simultaneous routing of different gases or samples.

The choice of valve type depends on factors such as the complexity of the GC system, the gases being analyzed, and the level of automation in the process.

Applications of Gas Chromatography Valves in the Semiconductor Industry

Gas chromatography valves serve several vital functions in semiconductor applications, each contributing to testing and analysis accuracy, efficiency, and reliability. The following are some of the primary applications:

- Purity Testing of Semiconductor Materials: High-purity gases and chemicals are essential for semiconductor manufacturing, and GC valves ensure that these materials are free of impurities that could affect production.

- Residual Gas Analysis: After processes like etching or deposition, residual gases in semiconductor fabrication equipment can be critical. GC valves help direct sample flow through the chromatograph for detailed analysis.

- Contaminant Detection: Volatile organic compounds (VOCs) and other contaminants can harm semiconductor devices. Gas chromatography valves enable the precise control of sample flow to detect even minute traces of pollutants.

- Process Monitoring: Various gases are used in semiconductor manufacturing, and their precise mixture and flow need to be monitored. GC valves are integral in ensuring the correct gas flow during these processes.

The Importance of Precision and Reliability in Gas Chromatography Valves

Even the slightest error in testing or analysis can have significant consequences in the semiconductor industry, including product failures, decreased yields, and increased production costs. For this reason, the precision and reliability of gas chromatography valves are of utmost importance.

- Minimizing Contamination:Leak-proof, high-performance valves reduce the risk of contamination, which is particularly crucial in the semiconductor industry, where even trace amounts of foreign substances can disrupt the performance of sensitive electronic components.

- Ensuring Consistency:Consistent valve performance is essential for reproducible results in quality control testing. Variability in valve operation can lead to consistent measurements and reliable data, potentially affecting decision-making in the production process.

- Maintaining Calibration:GC systems require regular calibration to ensure the accuracy of measurements. Valves that operate smoothly and consistently help preserve the integrity of the calibration process, preventing shifts in analytical results.

Choosing the Right Gas Chromatography Valves for Semiconductor Applications

Selecting the appropriate gas chromatography valves for semiconductor applications requires careful consideration of several factors:

- Compatibility with Gases: The types of gases used in the analysis will determine the valve material and design. To prevent damage or contamination, valves must be compatible with reactive or corrosive gases.

- Automation and Integration:Automation is key in high-throughput semiconductor testing environments. Valves that can be easily integrated into automated GC systems help streamline operations and reduce the risk of human error.

- Maintenance Requirements:Valves that are easy to maintain and service can help reduce downtime and ensure consistent performance over the long term.

- Performance Standards:It is essential to ensure that the valves meet industry-specific performance standards. High-quality valves will offer the precision, durability, and reliability needed in the semiconductor industry.

Conclusion

Gas chromatography valves are indispensable components in the semiconductor industry. They play a pivotal role in maintaining the precision and accuracy of gas chromatography systems used for quality control, contamination detection, and material analysis. The correct valve can improve the reliability of analytical results, reduce the risk of contamination, and ensure that the semiconductor manufacturing process adheres to stringent quality standards.

For more about gas chromatography valves for the semiconductor industry: ensuring precision and efficiency in analytical processes, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Tags

Recommended Products

-

Stainless Steel Ultra High Purity (UHP) High Pressure Manual Diaphragm Valve

-

7108L Cylinder Cap Connectors For Ultra High Purity Gases

-

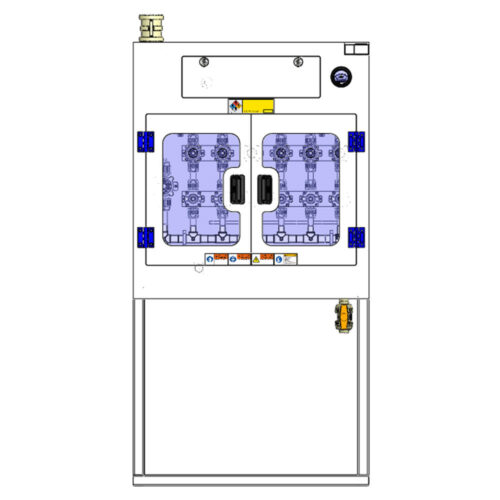

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

Ultra High Purity Pressure Gauge For Laboratory And Semiconductor JR Series

-

Line And Panel Mounting Adjustable Low Pressure Propane And Nitrogen Pressure Regulator JSR-3L & JSR-3LP Series

-

7102L Stainless Steel 316L SS Union Cross Ultra High Purity Long Arm Union Elbow Tee Cross Butt Weld Fittings

-

High Purity Stainless Steel Mini Tube Butt Weld Fittings For Semiconductor

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series