Gas Pipeline Engineering Design

The laboratory requires a constant carrier gas flow rate and high gas purity, providing stable gas with stable values and pressures for the analysis equipment selected by the laboratory. Establishing a centralized gas cylinder room can save limited laboratory space, and there is no need to cut off gas when replacing gas cylinders to ensure continuous gas supply. Users only need to manage fewer cylinders and pay less cylinder rent, as all points of use using the same gas come from the same gas source. This supply mode will ultimately reduce transportation costs, reduce the amount of gas remaining in empty bottles, and ensure good cylinder management. The centralized pipeline supply system can set up air outlets at the point of use, making the workplace design more reasonable and ensuring the safety of storage and use. Ensure that analysis and testing personnel are protected from the influence of toxic and harmful gases during experiments.

Laboratory Gas Pipeline Engineering Design

Jewellok has a professional gas pipeline engineering design team that can provide personalized gas pipeline engineering design solutions based on customer needs and the specific conditions of the laboratory.

Pipeline design and engineering

Our team of highly skilled engineers provide complete design solutions for some of the most challenging pipeline systems in the world, both in-house and by managing subcontracts with specialised external design houses. Based on an advanced knowledge of critical issues such as structural behaviour and hydrodynamics, we apply state-of-the-art solutions and technical engineering tools to deliver cost-effective, industry code-compliant pipeline solutions for our clients.

Jewellok Laboratory Gas Systems

Designing a laboratory means making critical decisions, especially when it comes to the delivery and management of your gases and cryogenics. So make the smart decision to work with an expert partner who knows the ins and outs of gas delivery and laboratory design.

Every aspect, every step of the way

As the nation’s largest supplier of industrial, medical and specialty gases and related equipment, we can assist in all facets of your project and help identify improvements for even the most complex system.

We work alongside your design team to build the best gas delivery and management systems for your customers. Turn to Jewellok for:

*Facility/laboratory gas distribution layout

*Risk-based central gas supply consulting and design

*Detailed specialty gas equipment needs assessment

*Material selection of equipment and piping

*Equipment and container sizing

*Safety consulting and safety management review

Whether you’re looking for a new design or a retrofit of an existing laboratory, we’ll work hand in hand to help you create the proper system for operational performance, safety and code conformance. From specifying purity levels to answering any gas-related technical questions, our associates have the expertise to help you make informed decisions and determine the right solutions for your project.

We work directly with:

*Architects

*Engineering firms

*Design-to-build firms

*MEP firms

*General contractors

Laboratory design—new construction or retrofit

*System guide for laboratory gases and cryogenics

*Turn-key laboratory piping design and installation solutions

*CAD drawing support—individual equipment and project specific layouts

*Coordinated and cooperative project management

Gas management systems

*Specialty gases, process chemicals and industrial applications

*Flammable, toxic, corrosive, high-purity, high-pressure and high-flow systems

*Pressure regulators

*Manifolds and changeover systems

*Point-of-use equipment

*Fully automated gas cabinets and safety systems

*Gas detection and monitoring support systems

Custom gas delivery systems

*Automated gas control systems

*High pressure system design

*Gas mixing systems

*Unique application solutions

Cryogenic supply, management and design

*Bulk cryogenic storage and delivery solutions

*Robust gas delivery systems

*On-site separation units

*Generators

*Tube trailers

*On-site and off-site cryorepositories

*Airgas Jewellok inventory management solutions

*Vacuum-insulated piping for Liquid Nitrogen

*Remote monitoring and alarm systems

Get the support you need and make sure your laboratory design project is covered from every angle—with expert assistance from the supplier that’s the right fit for you.

Laboratory Gas Pipeline

At present, with the continuous increase of laboratory equipment, the placement of gas cylinders has become a big problem. It is not safe and unsightly to put it indoors, and it also takes up a lot of space. In buildings without elevators, the handling of steel cylinders in high-rise laboratories is also a big problem.

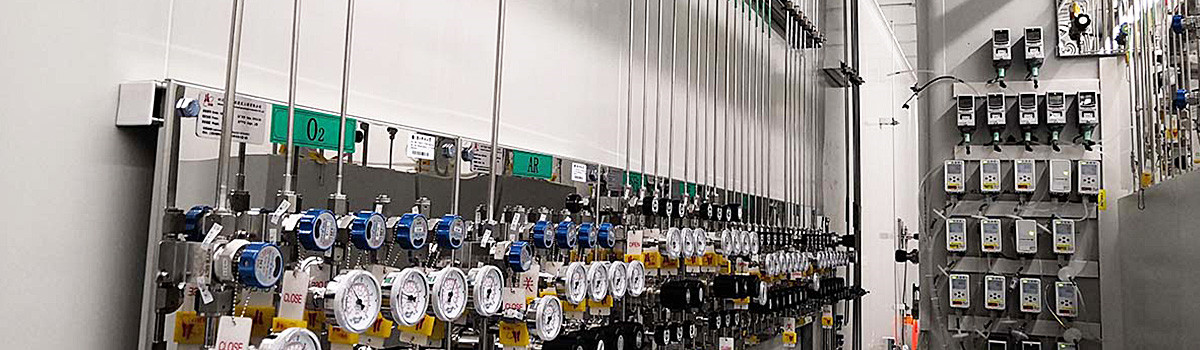

In response to this situation, a gas pipeline project was derived. The cylinders can be concentrated in a safe and convenient place, and various required gases can be introduced to each room through the gas path. According to the needs, the control box of the on-off valve, pressure gauge, pressure regulating valve, and gas flow meter can be installed in the room, which is safe, convenient, beautiful and space saving.

In the design and installation of laboratory gas pipeline engineering, the advantages of using centralized gas supply to transport high-purity gas are as follows:

1. Maintain gas purity

The dedicated gas cylinders are equipped with flushing valves to eliminate impurities introduced every time the gas cylinder is replaced and to ensure the purity of the gas at the end of the pipeline.

2. Uninterrupted gas supply

The gas circuit control system can switch between gas cylinders manually or automatically to ensure continuous gas supply.

The gas pipeline control system can switch between gas cylinders manually or automatically to ensure continuous gas supply.

3. Low pressure warning

When the air pressure is lower than the alarm limit, the alarm device can automatically start the alarm.

3. Stable gas pressure

The system adopts two-stage pressure reduction (the first stage is regulated by the air supply control system, and the second stage is regulated by the control valve at the point of use) to supply air, and a very stable pressure can be obtained.

4. High efficiency

Through the gas supply control system, the gas in the cylinder can be fully used, the residual gas margin can be reduced, and the gas cost can be reduced.

5. Easy to operate

All the gas cylinders are concentrated in the same location, which reduces operations such as transportation and installation, and saves time and costs.

6. Reduce the rent of gas cylinders

The use of a central gas supply system can reduce the requirements for the number of gas cylinders, thereby saving the rental and purchase costs of gas cylinders.

7. Reduce molecular sieve loss

Controlling the gas purity can effectively reduce the amount of molecular sieve used by several parties (cost savings).

8. No gas cylinders in the laboratory

The use of a central gas supply system means that there is no gas cylinder equipment in the laboratory, which has the following advantages:

—-Improve the sense of security, gas cylinders may cause gas leakage, fire and other dangerous situations.

—-Improve safety, the gas cylinder may fall to the ground and cause damage or injury.

—-Save space, remove the gas cylinder from the laboratory to free up more experimental space.